Introduction

When it comes to the performance and reliability of your 1999 Cummins engine, one critical component stands out: the Engine Control Module (ECM). This piece of technology plays a pivotal role in ensuring your engine runs smoothly and efficiently. Understanding the ECM's functions, location, and replacement process can help you maintain your vehicle in top condition. In this blog, we will delve into the intricacies of the 1999 Cummins ECM, providing you with detailed insights and practical information.

Table of Contents

What is a 1999 Cummins ECM?

The 1999 Cummins ECM, or Engine Control Module, is a sophisticated electronic unit responsible for controlling various engine functions. It is essentially the brain of the engine, managing the fuel injection, ignition timing, and other crucial parameters to optimize performance, fuel efficiency, and emissions.

Key Features:

- Microprocessor Control: Utilizes a microprocessor to process inputs from various sensors and make real-time adjustments.

- Diagnostic Capabilities: Can detect and log faults, providing valuable diagnostic information for troubleshooting.

- Programmable Settings: Allows for customization and tuning to meet specific performance requirements.

Where is the ECM Located on a 1999 Cummins Engine?

The ECM on a 1999 Cummins engine is typically located on the engine block itself. Specifically, you can find it on the left side of the engine, near the front. This location allows the ECM to easily connect to various engine sensors and actuators, ensuring efficient communication and control.

Quick Tip: Ensure the vehicle is turned off and cool before attempting to locate or handle the ECM to avoid injury or damage.

What is the Function of the ECM in a 1999 Cummins Engine?

The primary function of the ECM in a 1999 Cummins engine is to control and regulate the engine’s operation. It does this by processing data from numerous sensors that monitor conditions such as engine temperature, air pressure, and throttle position. Based on this data, the ECM adjusts the fuel injection, air intake, and ignition timing to ensure optimal performance.

Functions:

- Fuel Management: Controls the amount of fuel injected into the engine cylinders.

- Ignition Timing: Adjusts the timing of the spark plugs to ensure efficient combustion.

- Emission Control: Regulates the engine’s emissions to comply with environmental standards.

- Performance Monitoring: Continuously monitors engine performance and logs any anomalies or faults.

How to Install a New ECM on a 1999 Cummins Engine

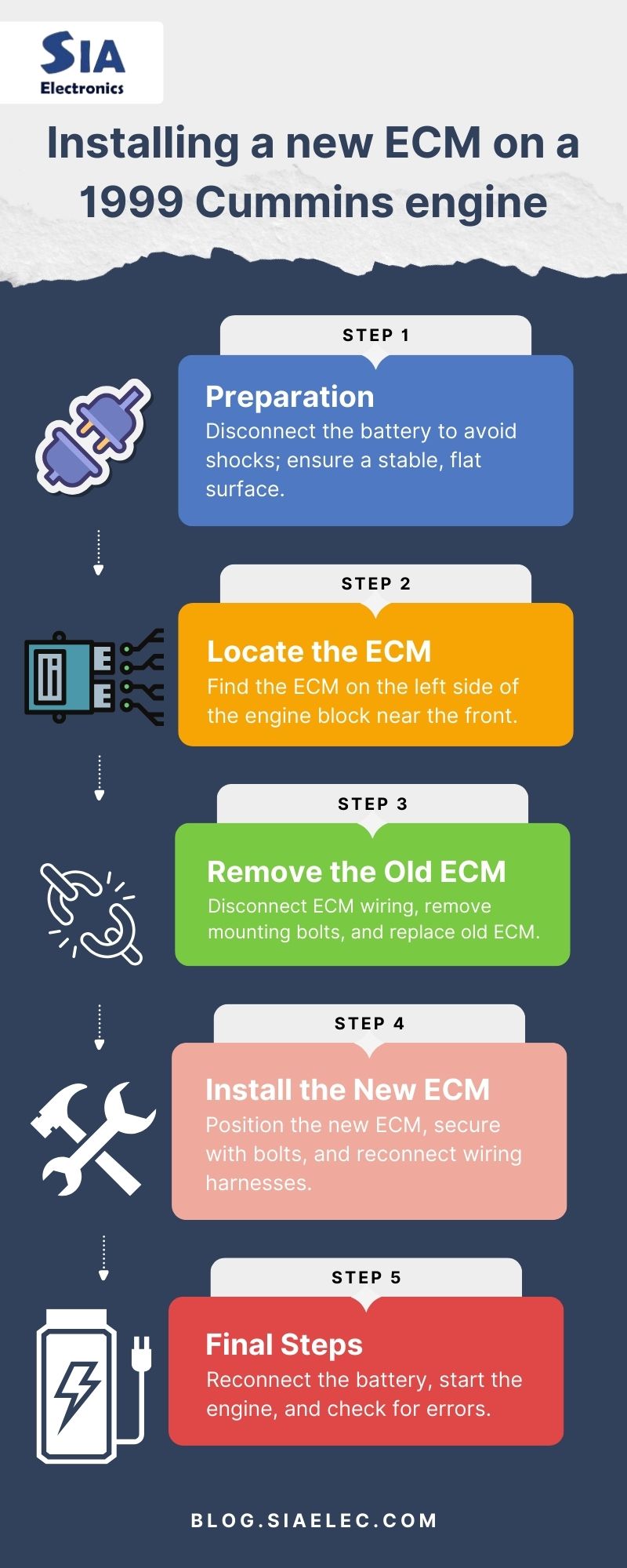

Installing a new ECM on a 1999 Cummins engine can be a straightforward process if you follow the correct steps. Here’s a step-by-step guide to help you through the installation:

Step-by-Step Guide:

- Preparation:

- Disconnect the battery to prevent electrical shocks.

- Ensure the vehicle is on a flat, stable surface.

- Locate the ECM:

- Find the ECM on the left side of the engine block near the front.

- Remove the Old ECM:

- Disconnect all the wiring harnesses connected to the ECM.

- Remove the mounting bolts and take out the old ECM.

- Install the New ECM:

- Place the new ECM in the same location as the old one.

- Secure it with the mounting bolts.

- Reconnect all the wiring harnesses to the new ECM.

- Final Steps:

- Reconnect the battery.

- Start the engine and check for any error codes or issues.

Important Note: The new ECM may require programming or calibration to ensure it functions correctly with your engine. Consult a professional if you are unsure about this step.

How Much Does it Cost to Replace a 1999 Cummins ECM?

The cost to replace a 1999 Cummins ECM can vary widely based on factors such as the type of ECM, where you purchase it, and whether you opt for professional installation.

Cost Breakdown:

- ECM Unit: Prices for a new ECM can range from $1,000 to $3,000 depending on the model and features.

- Labor Costs: If you choose to have a professional install the ECM, labor costs can range from $100 to $300.

- Programming Fees: Some ECMs require programming, which can add another $50 to $200 to the total cost.

Average Total Cost:

- DIY Installation: $1,000 to $3,000 (excluding programming fees)

- Professional Installation: $1,200 to $3,500 (including labor and programming fees)

Conclusion

The 1999 Cummins ECM is a vital component that ensures the efficient and smooth operation of your engine. Understanding its functions, location, and replacement process can save you time and money while maintaining the reliability of your vehicle. Whether you are a DIY enthusiast or prefer professional assistance, having the right knowledge about your ECM is crucial.

FAQs on

1999 Cummins ECM : Essential Guide to Engine Control Modules

-

1. What are the symptoms of a failing ECM?

Ans.

Common symptoms of a failing ECM include engine misfires, poor fuel economy, difficulty starting the engine, and the check engine light being on.

-

2. Can a damaged ECM be repaired?

Ans.

Yes, in some cases, a damaged ECM can be repaired by specialized technicians. However, depending on the extent of the damage, it might be more cost-effective to replace it.

-

3. How long does it take to replace an ECM?

Ans.

The replacement process itself can take between 1 to 2 hours. However, programming and calibration may add additional time.

-

4. What causes ECM failure?

Ans.

Common causes of ECM failure include electrical surges, water damage, extreme temperatures, and physical impact.

-

5. Can I drive with a faulty ECM?

Ans.

While it is possible to drive with a faulty ECM, it is not recommended as it can lead to poor engine performance and potential damage to other components.

-

6. What tools are needed to replace a 1999 Cummins ECM?

Ans.

Basic hand tools such as wrenches and screwdrivers are needed to replace the ECM. Additionally, a diagnostic scanner might be required for programming the new unit.