Cummins ISX ECM Location: Easy Guide to Find Your ECM

Looking for the Cummins ISX ECM location? Our guide simplifies the process, providing clear instructions and visuals to help you find and understand your engine's ECM quickly.

Looking for the Cummins ISX ECM location? Our guide simplifies the process, providing clear instructions and visuals to help you find and understand your engine's ECM quickly.

When maintaining or troubleshooting a Cummins ISX engine, understanding the location and function of the Engine Control Module (ECM) is crucial. The ECM is the brain of the engine, managing everything from fuel injection to emissions control. In this blog, we will explore the specifics of the Cummins ISX ECM location, including its location, the tools needed to access it, and how to ensure it is properly connected.

The Cummins ISX ECM, or Engine Control Module, is a sophisticated electronic device that controls and monitors the engine's performance. It ensures optimal operation by regulating fuel injection, air intake, and emission systems. The ECM collects data from various sensors and makes real-time adjustments to keep the engine running efficiently and within regulatory limits. The Cummins ISX ECM plays a pivotal role in maintaining engine performance, fuel efficiency, and emissions standards.

The ECM on a Cummins ISX engine is typically mounted on the left side of the engine, near the front. It is attached to the engine block, close to the fuel pump. This location allows easy access for diagnostic and maintenance purposes while keeping the module protected from excessive heat and vibration. The precise location may vary slightly depending on the model year and specific configuration of the engine, but it is generally found in this area.

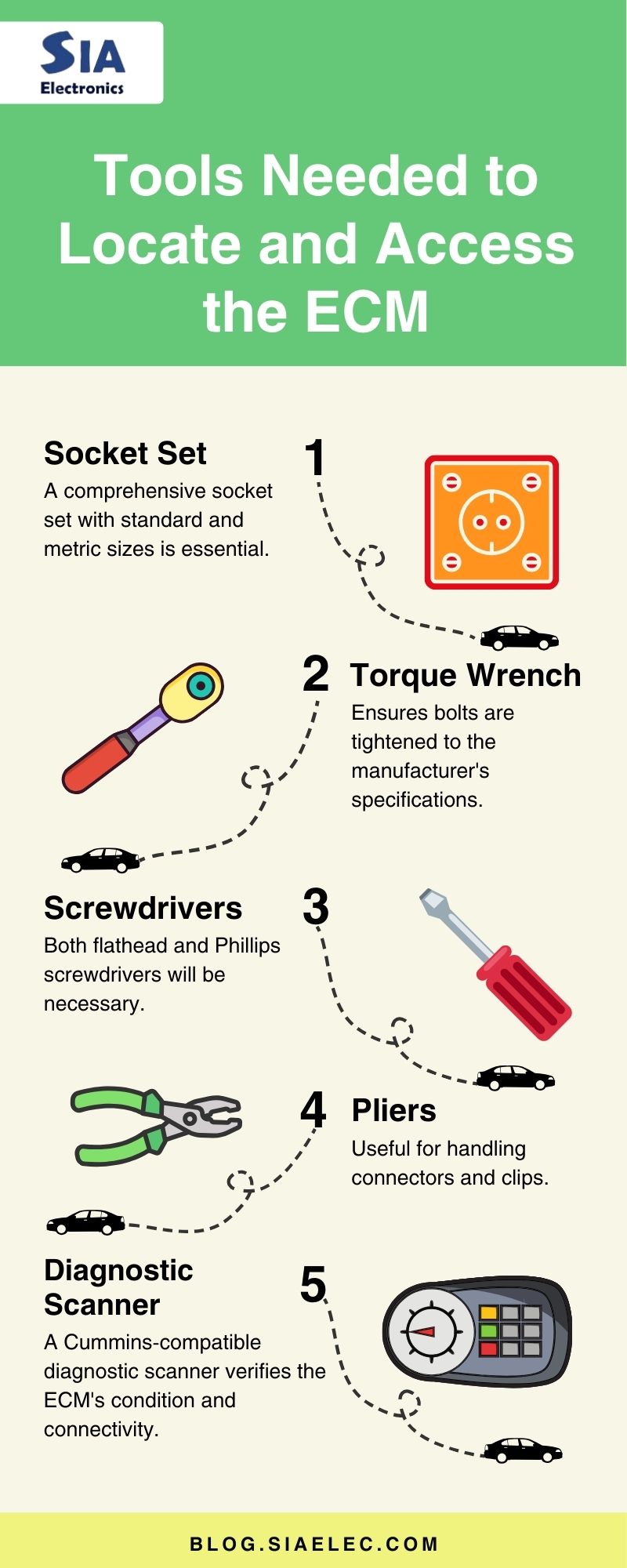

Locating and accessing the ECM on a Cummins ISX engine requires a few basic tools. Here is a list of essential tools you will need:

While the general location of the ECM on Cummins ISX engines is consistent, there can be slight variations across different models and years. For instance:

Ensuring the ECM is properly connected is vital for the engine's performance. Here are steps to verify the connection:

Understanding the location and functionality of the Cummins ISX ECM is essential for effective engine maintenance and troubleshooting. With over 20 years of experience, SIA Electronics is an industry leader in the re-manufacturing of automotive electronic control modules and ECUs. Whether you need to locate the ECM on a Cummins ISX engine or ensure it is properly connected, having the right knowledge and tools can make the process seamless. Regular inspections and proper maintenance are key to keeping your engine running smoothly.

The ECM, or Engine Control Module, in a Cummins ISX engine manages critical functions such as fuel injection, air intake, and emission control. It ensures the engine runs efficiently and complies with emission regulations by making real-time adjustments based on data from various sensors.

Replacing the ECM on a Cummins ISX engine requires technical knowledge and specialized tools. While it is possible to do it yourself, it is recommended to have a professional technician handle the replacement to ensure it is done correctly and to avoid potential damage.

Common symptoms of a failing ECM include engine misfires, poor fuel efficiency, difficulty starting the engine, and the check engine light turning on. If you experience any of these issues, it is advisable to have the ECM checked and diagnosed by a professional.

The ECM should be inspected regularly as part of routine engine maintenance. It is advisable to check the ECM and its connections during every major service or if you experience any engine performance issues.

Yes, a faulty ECM can negatively impact the emissions of your Cummins ISX engine. The ECM regulates the engine's emission control systems, and any malfunction can lead to increased emissions and non-compliance with environmental regulations.

Yes, it is often necessary to reprogram the ECM after installation to ensure it is correctly configured for your specific engine and vehicle. This process requires specialized diagnostic tools and should be performed by a qualified technician.