Introduction

In the world of automotive technology, ECM (Engine Control Module) calibration plays a pretty crucial role in optimizing vehicle performance and ensuring compliance with environmental regulations - the ECM is the electronic heart of your vehicle and any small miscaliberation can cause big issues.

SIA Electronics is a trusted name in automotive electronic control modules and ECU re-manufacturing, bringing over 20 years of expertise to the field. Our services extend to mass air flow sensors, anti-lock brake computers (EBCMs), and hydraulic units for both domestic and foreign vehicles.

Cummins INSITETM is a Microsoft Windows based electronic service diagnostic software to troubleshoot Cummins electronic engines. In other words, one of the leading tools for ECM calibration of Cummins engines is Cummins Insite. Below we will explore what Cummins Insite ECM calibration is, how it works, its benefits, common issues, and associated costs.

Table of Contents

What is Cummins Insite ECM Calibration?

As discussed above, Cummins Insite is a software for ECM caliberation of Cummins engine. Calibration refers to the process of adjusting and optimizing outputs - in this case, for the Engine Control Module (ECM) settings using Cummins Insite software. This tool is designed with five-levels of management, for managing and fine-tuning the ECM, which controls various engine functions to improve performance, efficiency, and compliance with emissions standards.

Key Points:

- ECM Calibration: Adjusting the ECM settings to achieve optimal engine performance.

- Cummins Insite: A software tool used for detailed ECM calibration and diagnostics.

How Does ECM Calibration Work with Cummins Insite?

ECM calibration with Cummins Insite involves several steps to ensure the ECM is configured correctly for the engine’s specific requirements.

Steps for the Caliberation process:

- Data Collection: Cummins Insite gathers data from the vehicle’s engine and ECM, including performance metrics and fault codes.

- Parameter Adjustment: Technicians use the software to adjust various parameters, such as fuel injection timing, air-fuel ratio, and turbocharger settings.

- Testing and Validation: The adjusted parameters are tested in real-world conditions to ensure they meet performance and emission standards.

- Finalization: Once validated, the new settings are applied, and the ECM is calibrated to enhance engine efficiency and reliability.

In other words, the current

Important Considerations:

- Software Version: Ensure you have the latest version of Cummins Insite for compatibility and updated features.

- Technician Expertise: Calibration should be performed by trained professionals to avoid potential issues.

Benefits of Calibrating the ECM with Cummins Insite

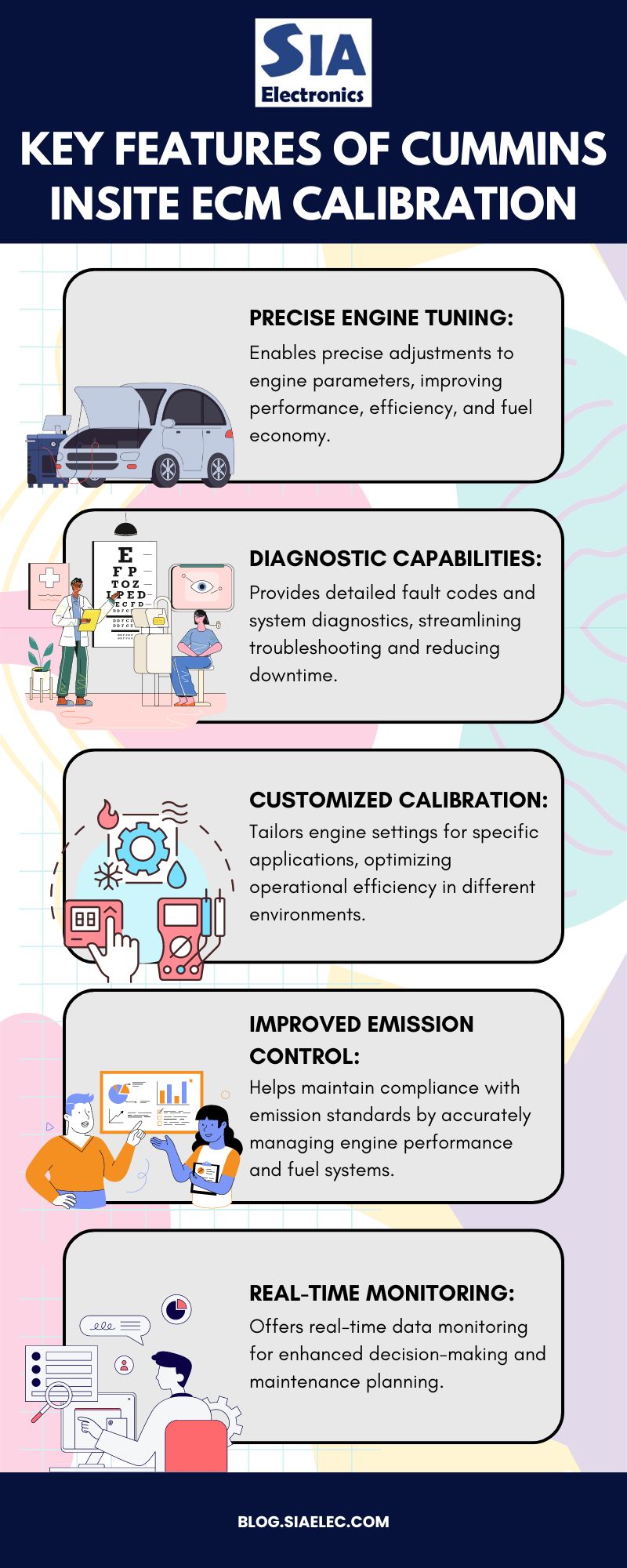

Calibrating the ECM with Cummins Insite offers several advantages that can significantly impact vehicle performance and operational efficiency.

Key Benefits:

- Enhanced Performance: Optimizes engine performance for better power output and fuel efficiency.

- Improved Fuel Economy: Adjustments can lead to more efficient fuel use, reducing overall fuel consumption.

- Regulatory Compliance: Ensures the vehicle meets emission standards, avoiding legal penalties and contributing to environmental protection.

- Increased Reliability: Reduces the likelihood of engine malfunctions and improves overall vehicle longevity.

Statistical Insight:

- Fuel Savings: Proper ECM calibration can result in fuel savings of up to 10% in most cases.

- Emission Reduction: Effective calibration can reduce harmful emissions by up to 20%.

Common Issues Encountered During Cummins Insite ECM Calibration

While Cummins Insite is a powerful tool, some common issues may arise during ECM calibration. These are typically issues that can arise with any software.

Common Issues:

- Software Compatibility: Older versions of Cummins Insite may not support newer ECM models, so please check the version thoroughly.

- Incorrect Data: Inaccurate data collection can lead to improper calibration settings. This is usually the problem.

- Technical Errors: Calibration may fail due to technical issues or software bugs.

- Training Gaps: Though it is rare, inadequate technician training can result in incorrect calibration adjustments.

Solutions:

- Regular Updates: Keep the software up-to-date to ensure compatibility.

- Accurate Diagnostics: Ensure accurate data collection and diagnosis before calibration.

- Training: Invest in technician training to handle complex calibration tasks effectively.

Cost of Using Cummins Insite for ECM Calibration

The cost of using Cummins Insite for ECM calibration can vary based on several factors, including the complexity of the calibration and the service provider.

Cost Factors:

- Software Licensing: The cost of Cummins Insite software and any required updates.

- Service Charges: Fees for professional calibration services.

- Vehicle Type: Calibration costs may differ depending on the vehicle’s make and model.

Average Costs (please confirm the latest prices from the website link provided above):

- Software License: $500 to $1,000 (one-time or subscription-based).

- Calibration Service: $150 to $500 per vehicle, depending on the complexity.

Cummins Insite ECM calibration is a critical process - for both optimizing engine performance and ensuring compliance with emission standards. By understanding what ECM calibration is, how it works, its benefits, common issues, and associated costs, vehicle owners - people or businesses - can make informed decisions about maintaining and enhancing their engine systems. At SIA Electronics, we offer expert ECM re-manufacturing and calibration services, backed by over 20 years of industry experience. Whether you’re seeking to improve engine efficiency or ensure regulatory compliance, we can meet your needs with precision and reliability.

FAQs on

Cummins Insite ECM Calibration : Enhance Engine Performance and Efficiency

-

What is the purpose of ECM calibration?

Ans.

ECM calibration adjusts the settings of the Engine Control Module to enhance engine performance, fuel efficiency, and emissions compliance.

-

How often should ECM calibration be performed?

Ans.

ECM calibration should be performed during regular maintenance intervals or when noticeable performance issues arise.

-

Can ECM calibration be done remotely?

Ans.

No, ECM calibration typically requires direct access to the vehicle’s ECM and is performed onsite by a trained technician.

-

Is ECM calibration necessary for all vehicles?

Ans.

While not always necessary, calibration is crucial for optimizing performance and ensuring compliance with emission standards, especially in commercial vehicles.

-

What happens if ECM calibration is done incorrectly?

Ans.

Incorrect calibration can lead to engine performance issues, increased fuel consumption, and potential legal penalties for non-compliance with emission regulations.

-

How can I choose a reliable service provider for ECM calibration?

Ans.

Look for providers with extensive experience, positive customer reviews, and certified technicians to ensure accurate and reliable calibration services.