Introduction

When you hear the term "ECM," what comes to mind? For many, it's a mysterious component crucial to a vehicle's operation, but what exactly does it do? Understanding the Electronic Control Module (ECM) is essential for anyone involved in the trucking industry. This blog delves into the heart of what is an ECM in truck?, its role in controlling the engine, its location, and its importance. With insights from SIA Electronics, an industry leader in remanufacturing automotive electronic control modules, we aim to provide a comprehensive overview.

Table of Contents

What is ECM?

The Electronic Control Module (ECM), also known as the Engine Control Unit (ECU), is the brain of a truck's engine. It is a computer that monitors and controls various engine functions to ensure optimal performance, fuel efficiency, and emissions control. The ECM collects data from various sensors and uses this information to make real-time adjustments to the engine's operation.

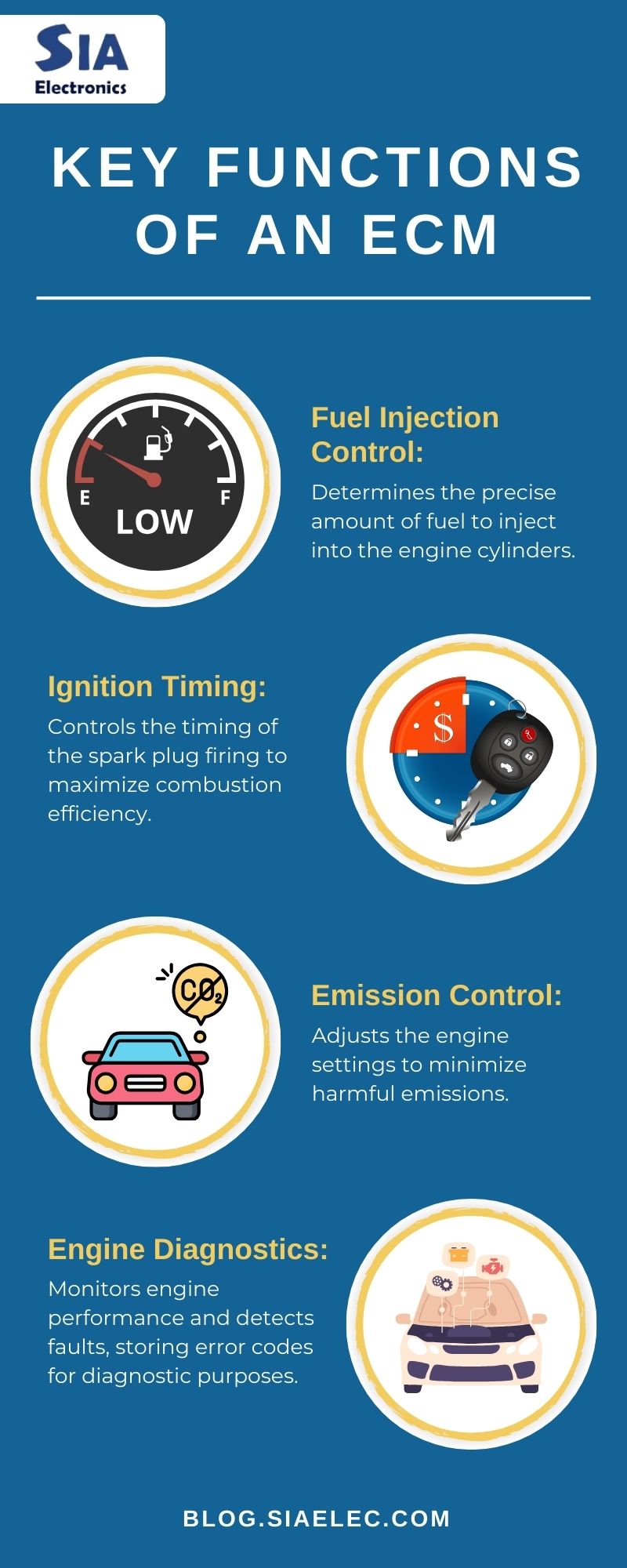

Key Functions of an ECM:

- Fuel Injection Control: Determines the precise amount of fuel to inject into the engine cylinders.

- Ignition Timing: Controls the timing of the spark plug firing to maximize combustion efficiency.

- Emission Control: Adjusts the engine settings to minimize harmful emissions.

- Engine Diagnostics: Monitors engine performance and detects faults, storing error codes for diagnostic purposes.

How Does the ECM Control the Engine in a Truck?

The ECM receives input from various sensors throughout the truck, such as the oxygen sensor, throttle position sensor, and mass air flow sensor. Based on this data, the ECM adjusts the engine parameters to ensure optimal performance. For instance, if the oxygen sensor detects a lean fuel mixture, the ECM will increase the fuel injection to balance the air-fuel ratio.

Control Mechanisms:

- Air-Fuel Ratio: Ensures the engine runs at the most efficient air-fuel mixture.

- Ignition Timing: Adjusts the timing of spark plug ignition to optimize combustion.

- Idle Speed Control: Regulates the engine's idle speed to prevent stalling and ensure smooth operation.

- Variable Valve Timing: Adjusts the timing of the engine valves for improved performance and efficiency.

Where is the ECM Located in a Truck?

The location of the ECM in a truck can vary depending on the make and model, but it is typically found in a few common areas:

- Engine Compartment: Often mounted on the firewall or near the engine itself.

- Cabin: Under the dashboard or behind the glove compartment.

- Chassis: Mounted on the frame rail or other structural components.

The ECM's location is chosen to protect it from excessive heat, vibration, and moisture, ensuring it remains functional and reliable.

Can a Truck Run Without an ECM?

In short, no, a truck cannot run without an ECM. The ECM is essential for controlling the engine's critical functions. Without it, the engine would not receive the necessary inputs to operate efficiently, leading to poor performance, increased emissions, and potential engine damage.

Consequences of a Faulty or Missing ECM:

- Engine Stalling: The engine may not start or could stall unexpectedly.

- Reduced Fuel Efficiency: Without precise fuel control, fuel consumption would increase.

- Increased Emissions: The truck would fail to meet emission standards.

- Diagnostic Challenges: Identifying and fixing engine problems would be more difficult.

What is the Lifespan of an ECM in a Truck?

The lifespan of an ECM can vary based on several factors, including the truck's usage, operating conditions, and maintenance practices. On average, an ECM can last anywhere from 5 to 10 years. However, some ECMs may last longer with proper care and maintenance.

Factors Affecting ECM Lifespan:

- Environmental Conditions: Exposure to extreme temperatures, moisture, and vibrations can shorten the ECM's lifespan.

- Electrical Issues: Voltage spikes, short circuits, and other electrical problems can damage the ECM.

- Maintenance: Regular maintenance and prompt repair of sensor issues can prolong the ECM's life.

SIA Electronics: Your Trusted Partner in ECM Remanufacturing

At SIA Electronics, we specialize in the remanufacturing of automotive electronic control modules and ECUs for both domestic and foreign vehicles. With over 20 years of experience, we provide high-quality remanufactured ECMs that meet or exceed OEM standards. Our services also extend to mass air flow sensors, anti-lock brake computers (EBCMs), and anti-lock brake hydraulic units.

Why Choose SIA Electronics?

- Expertise: Over two decades of experience in ECM remanufacturing.

- Quality: Our remanufactured ECMs undergo rigorous testing to ensure reliability and performance.

- Customer Support: Dedicated support team to assist with all your ECM needs.

- Warranty: Comprehensive warranty coverage for peace of mind.

FAQs on

what-is-ecm-on-a-truck? A comprehensive guide

-

1. What are the main functions of an ECM in a truck?

Ans.

The ECM, or Electronic Control Module, plays a critical role in managing a truck’s engine by controlling fuel injection, ignition timing, emission settings, and engine diagnostics. It adjusts these parameters based on data from various sensors to ensure optimal engine performance and efficiency.

-

2. How does the ECM impact a truck's fuel efficiency and emissions?

Ans.

The ECM optimizes fuel efficiency and emissions by adjusting the air-fuel ratio, ignition timing, and other engine parameters. It ensures that the engine runs with the ideal mixture of air and fuel and controls the timing of combustion to reduce emissions and enhance overall efficiency.

-

3. Can the location of the ECM affect its performance and lifespan?

Ans.

Yes, the ECM's location is crucial for its performance and lifespan. It is typically mounted in areas protected from extreme temperatures, moisture, and vibrations, such as the engine compartment, cabin, or chassis. Proper placement helps prevent damage and ensures reliable operation.

-

4. What are the symptoms of a failing ECM in a truck?

Ans.

Symptoms of a failing ECM include engine stalling or difficulty starting, reduced fuel efficiency, increased emissions, and challenges with diagnosing engine problems. A malfunctioning ECM can lead to poor engine performance and potentially severe damage if not addressed promptly.

-

5. How often should an ECM be replaced or remanufactured?

Ans.

The lifespan of an ECM can range from 5 to 10 years, depending on usage, environmental conditions, and maintenance. Regular inspections and prompt repairs can extend its life. Remanufactured ECMs from reputable providers can offer a cost-effective solution when replacement is necessary.

-

6. What services does SIA Electronics offer for ECMs and other automotive electronics?

Ans.

SIA Electronics specializes in remanufacturing ECMs and other automotive electronic components, including mass air flow sensors, anti-lock brake computers (EBCMs), and hydraulic units. They provide high-quality remanufactured parts, rigorous testing, and comprehensive customer support with warranty coverage.